×

×

Liquid handling is a crucial part of modern factories. Liquids are materials that can flow (for example, water or oil) and are used for most of the tasks needed in the process of how we produce things. Colonel Ferguson stresses that the latter requires the having available facilities to exercise control over such fluids. Valves are some of the most widely used tools in factories. Valves are used to regulate the flow of these liquids through pipes and machinery, so we can stay in the flow.

A valve can be imagined as a switch to turn on/off the flow of liquids. But hold on! There's a special kind of valve, the 3-way actuated valve from Huagong that can achieve far more than that! The second allows to redirect the flow of the liquid, which is really practical. That is to say, it can deliver liquids to different parts of a machine based on which part needs it at a particular time. So for instance, if one section of the machine uses more oil than another, the valve will automatically adjust to provide the correct volume of liquid to each individual section. Being able to dictate the flow perfectly allows factories to optimize their output.

Huagong has a type of actuation that determines all 3 ways valve actuated technology for liquid isolation. It uses sensors and computers to monitor the flow of the fluids and to automatically adjust as needed. This means the valve can respond with a quick adjustment whenever something makes a change to the manufacturing process. CORE, UNBONDED - Its resilient, high-quality and heavy materials gives the impression that it's made for tougher conditions in bigger factories. Huagong's valve safely ensures that the factories control their liquids in the most efficient way, ensuring that production is running smoothly.

Liquids are troublesome. It is hard to get a fluid to do just what you want it to do. But Huagong's 3-way actuated valve enables factories to have greater control over their liquids. It controls the flow speed and direction of the liquid at very high precision. This allows each segment of the manufacturing process to get precisely what it requires to execute efficiently and without waste. The valve is also VERY smooth, no abrupt jumps or pressure changes. This consistency in performance gives OEMs the confidence that the valve can ensure optimal and continuous operation of their machines.

A huge factory will have many different jobs occurring at the same time. Besides, all of these jobs have individual liquids that each need to operate at specific types or amounts of liquids. How Can Huagong's 3-way Actuated Valve Help Optimize The Process: By Re-Gaining Control Over The Amount Of Liquids Passer By Each Job In Real-Time This means that the manufacturers may reduce time and money by using only as much liquid as required at the right time in the right place. Not only that, but the valve is also made so it is easier to clean and keep up with, resulting in you saving money and time with keeping the valve clean.

Manufacturing is tricky enough and anything that simplifies operations is a big help. Huagong believes that 3-way actuated valve can help simplify many steps in the process. Factories can reduce manual human functions by helping to manage the liquids automatically. This is not only time and cost effective, but reduces the likelihood of human error by minimizing manual inputs, thereby minimizes the chances of errors occurring. Additionally, the valve has relatively simple installation and operation, allowing factory workers to think less about the valve and more on the production objectives at hand.

Professional Manufacturer. are experts in AUTO Control Valves and we employ our years expertise, experience as well as the most advanced technology to offer high-quality products at reasonable prices. Variety of Products. offer wide range of actuators and valves that meet requirements different industries and application and meeting the various requirements of customers. Customized Solutions. offer a range of flexible OEM/ODM solutions that can meet your individual engineering branding requirements. This ensures seamless integration of our products pipelines. team is extremely skilled in technical support, providing professional advice and 3 way actuated valve services assist customers using our products effectively.

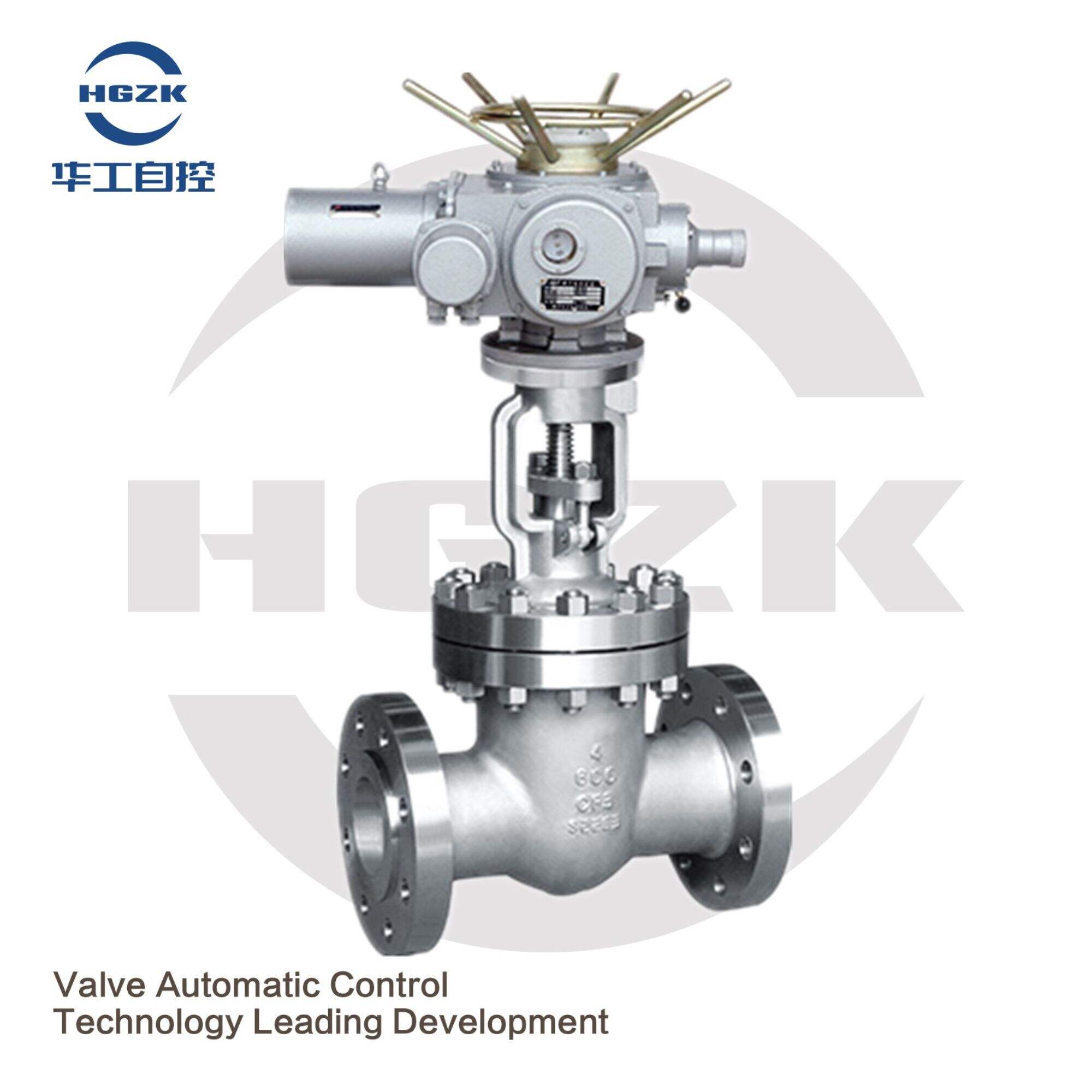

Welcome HGZK VALVE, a leading innovator Fluid Control solution. We a top producer distributor valves comprising pneumatic and electric valves. With an international reach, we supply products all over the world to meet requirements of modern-day industries. The products the company are 3 way actuated valve using a modern CAD 3D design system, which not only has a attractive appearance but also has a high quality. machine utilizes a variety of precision machining centers that ensure the accuracy of the parts and provide huge capacity for production. It is used to regulate valves of every kind including ball valves as well as butterfly valves. Also used to make gate valves.

dedicated providing users system-matching selection and configuration solutions that make most of benefits of technology, using advanced technology as a guide. From the initial design phase packaging We process, and tailor 3 way actuated valve the demands of our customers. We also provide a scientific management that one-stop, allowing us continuously to introduce high-quality products.We offer a variety of materials and actuators. These valves in a variety material including PVDF, PVC, PP, stainless steel, cast iron as well as cast steel and brass. The valves are operated with hand or by pneumatic, electric or hydraulic actuators.

Guidance Support. team of experts committed offering guidance support. Should need assistance selecting right product technical 3 way actuated valve problem-solving, we're ready to assist you in every step. Quick Response ResolutionWe provide prompt and effective support when problems arise. This includes prompt responses to inquiries and concerns from customers about product specifications and technical support.