×

×

Electric rotary actuators Electric actuators are a new type of device that can convert electrical energy directly into mechanical motion to control the drive shaft rotation. Such actuators have various advantages for industrial use, including higher precision, speed and reproducibility versus traditional pneumatic or hydraulic systems. Due to technologies elapsed electric rotary actuator is an essential part of automation & control industry used in different sectors of industries that increases productivity and reduces costs.

A particular advantage of electric powered rotary actuation is to be able to gain accurate control over the rotation of a member. In contrast to pneumatic or hydraulic systems where air pressure or fluid acts on a piston, electric actuators provide more accurate and repeatable performance, making it well suited for applications requiring close tolerances.Such applications are those where otherwise large production and/or normal control costs contribute to maintaining tight tolerance limits. What’s more, electric rotation actuators are energy-saving and power only during operation, which brings cost saving factors in for the end user but also the environmental. Electric actuators are also incredibly small and easy to install into existing units, therefore making them both versatile and easily adaptable for a variety of manufacturing methods.

There are a number of critical features to consider when selecting an electric rotary actuator, all ensuring that you get the best performance and most reliable product possible. Some of the main features that you should consider are the torque performance, speed rates, duty cycle as well as actuator precision. At greater torque outputs and speeds the better control and performance to rotate heavy loads or move rapidly a largely members. Along with a high duty cycle the actuator is able to work non-stop without heating to contribute any efficiency loss. Accuracy is also important, since it affects the repeatability and accuracy of movement of the actuator, which may be particularly critical in applications involving precise positioning or motion control.

Electric rotary actuators are at the forefront of increased efficiency and cost savings in industrial applications as they provide faster cycle times, more accurate repeatable stopping, less down time and lower maintenance expense when compared to typical pneumatic or hydraulic systems. Through automation of repetitive work and accurate movement control, electric actuators can optimise the manufacturing process, reduce downtime and improve efficiency. And because electric actuators require less energy to operate, users save money on power consumption and maintenance costs while helping the environment.

The electric rotary actuator sector is experiencing several trends which will be instrumental in dictating the future of automation and control systems. Smart technologies, such as IoT connectivity and controls based on AI, are among the predominant trends for electric actuators in enabling remote monitoring, predictive maintenance and performance optimization. Another trend is the miniaturization and lightweighting of actuators at high torque outputs and speed levels influenced by growing needs for efficiency and compact design in industrial applications. In addition, the transition to "green" options - from energy efficient actuators through sustainable materials - aligns with an industry desire to minimize carbon footprints and encourage eco-friendly behavior.

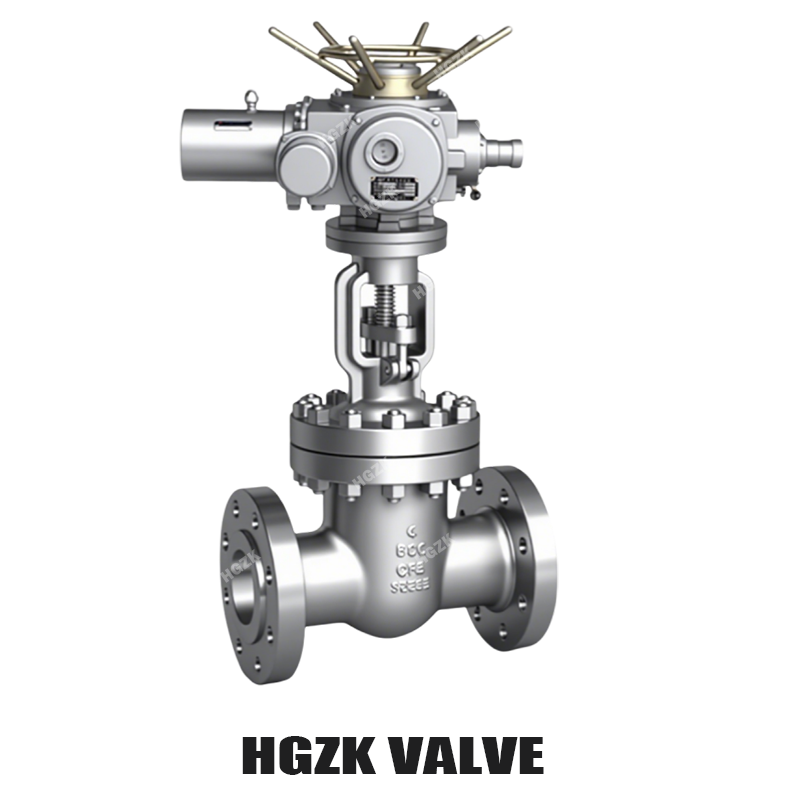

HGZK VALVE is leader in field fluid control solutions fluid control. We are a major manufacturer distributor of valve products including electric pneumatic valves. distribute products around the world to meet the demands diverse industries. Modern CAD 3D systems electric rotary actuator to optimize the company's products, which characterized by beautiful appearance and premium finish. machine utilizes a variety machining centers that are precision to guarantee accuracy of the components and to create an enormous production capacity. It used to regulate valves of all types including ball valves as well as butterfly valves. Also used to make gate valves.

company committed to providing users system matching selection configuration price performance ratio solutions, using high-tech as guideline and fully exploiting the technological advantages. From conception to production packaging the products create modify meet customer needs. also offer scientific management service that is one-stop which allows us constantly to create high-quality items.We have a variety of electric rotary actuator and actuators. valves are made of PVC, PP PVDF cast iron, stainless brass, cast steel and cast steel. Our valves can be operated manually or using electric, pneumatic, or hydraulic actuators.

Professional Manufacturer. are experts in AUTO Control Valves and we make use our vast expertise, experience the latest technologies to offer top-quality products at reasonable prices. A wide range product. offer a wide range electric rotary actuator actuators, accommodating requirements a variety of industries and uses to meet the diverse needs of our clients. Customized Solutions. offer flexible OEM/ODM options to meet unique needs in terms of branding and engineering. This guarantees seamless integration of our products into pipelines. Our team is awash with technical experience, providing expert support and consultancy services to ensure that customers are able to understand and make use of our products properly.

Guidance and Support. team of experts is committed to offering guidance support. We're here to help you, whether in the selection products, technical specifications, problems to solve. respond quickly and resolutionWe offer quick and efficient assistance when issues occur. This includes timely responses to queries and electric rotary actuator of customers on specifications products as well as technical assistance.