×

×

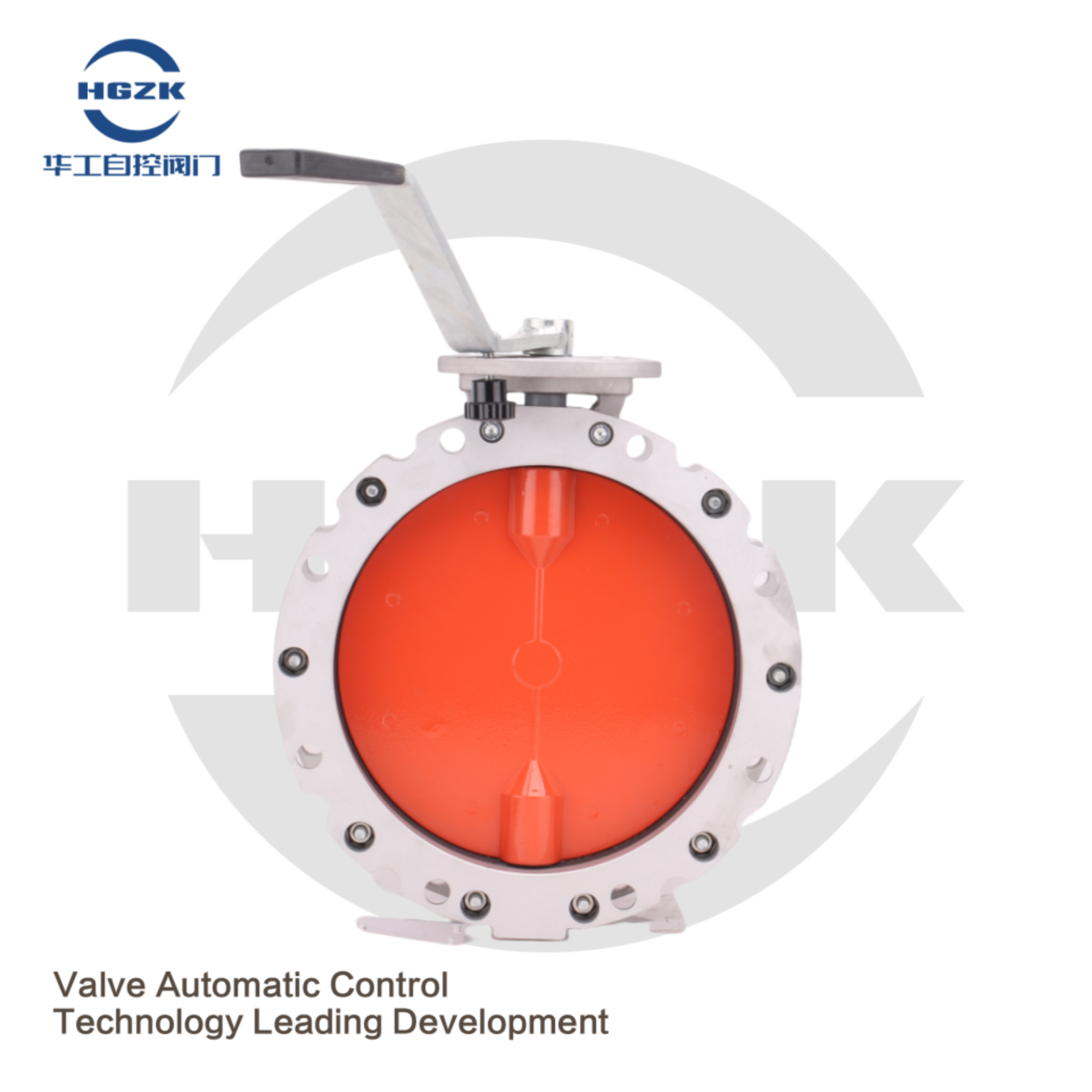

Three important parts work and function together in a lug type. First is the body, which serves as the main house of the valve. This organ has two holes/openings which allow liquids to flow through when the valve is open. Next up, there’s a disk that behaves like a moving door. When the valve is opened, the ow of liquid results in the disk moving upwards, in between a huge ow path. During the closing of the valve, the disk drops down and prevents the liquid from passing. The last segment of the device is called the stem — essentially an arm that connects a disk to a handle. This handle allows the person to control when the valve opens and closes.

These specialized valves are found in a lot of critical places. Lug type valves help maneuver liquids around at water treatment centers, factories and other large work environments. These valves are so amazing that they can be inserted into pipes without removing the entire pipe. They are therefore incredibly simple to install and maintain, saving time and money.

Materials for the construction of lug type valves. Some are made of steel, a material that is strong and tough. Others are bronze, which works well with water. The material is selected according to the type of liquid that will flow through the pipe and the temperature of that liquid. Some have arms that are great for wet spaces; others are just ideal for water traveling.

Here are several things that a user considers when opting for lug type valve. They consider what liquid will pass through the valve, how hot or cold the liquid is and where the valve is used. Like choosing the perfect tool for a special job!

It sort of takes a little work to install a lug type valve. The first step is to prevent the liquid from entering the pipe. Next, you carefully take out the old valve and replace it with a new one. You want to be gentle but don’t want anything too tight. If you apply too much pressure, either the internal valve will get damaged or the pipe will break.

Maintaining a lug type valve is crucial as well. Regular checking of these valves by the individuals utilizing them guarantees that everything is running well. They identify any fissures or parts that may be losing their integrity. They also ensure to have the moving parts well oiled, similar to how one would oil chains of a bicycle so that they can move smoothly.

So lug type valves are the superheroes of pipe! These have a variety of different uses and are easily maintained. They assist in transporting liquids safely and smoothly in a wide range of locations These valves are always doing hard work whether that be moving water in a treatment plant or helping oil flow in a factory.

Professional Manufacturer. are experts in AUTO Control Valves and we make use our vast expertise, experience the latest technologies to offer top-quality products at reasonable prices. A wide range product. offer a wide range lug type valve actuators, accommodating requirements a variety of industries and uses to meet the diverse needs of our clients. Customized Solutions. offer flexible OEM/ODM options to meet unique needs in terms of branding and engineering. This guarantees seamless integration of our products into pipelines. Our team is awash with technical experience, providing expert support and consultancy services to ensure that customers are able to understand and make use of our products properly.

company committed to providing users system matching selection configuration price performance ratio solutions, using high-tech as guideline and fully exploiting the technological advantages. From conception to production packaging the products create modify meet customer needs. also offer scientific management service that is one-stop which allows us constantly to create high-quality items.We have a variety of lug type valve and actuators. valves are made of PVC, PP PVDF cast iron, stainless brass, cast steel and cast steel. Our valves can be operated manually or using electric, pneumatic, or hydraulic actuators.

Welcome HGZK VALVE, a leading innovator Fluid Control solution. We a top producer distributor valves comprising pneumatic and electric valves. With an international reach, we supply products all over the world to meet requirements of modern-day industries. The products the company are lug type valve using a modern CAD 3D design system, which not only has a attractive appearance but also has a high quality. machine utilizes a variety of precision machining centers that ensure the accuracy of the parts and provide huge capacity for production. It is used to regulate valves of every kind including ball valves as well as butterfly valves. Also used to make gate valves.

Advice Support. team of experts will provide guidance and support. available 24/7 to assist with issue, be it selecting best product, technical specs, or problems to solve. Rapid Response ResolutionWe provide quick and efficient support when problems occur. This includes prompt responses to lug type valve and concerns of customers about product specifications and technical assistance.