×

×

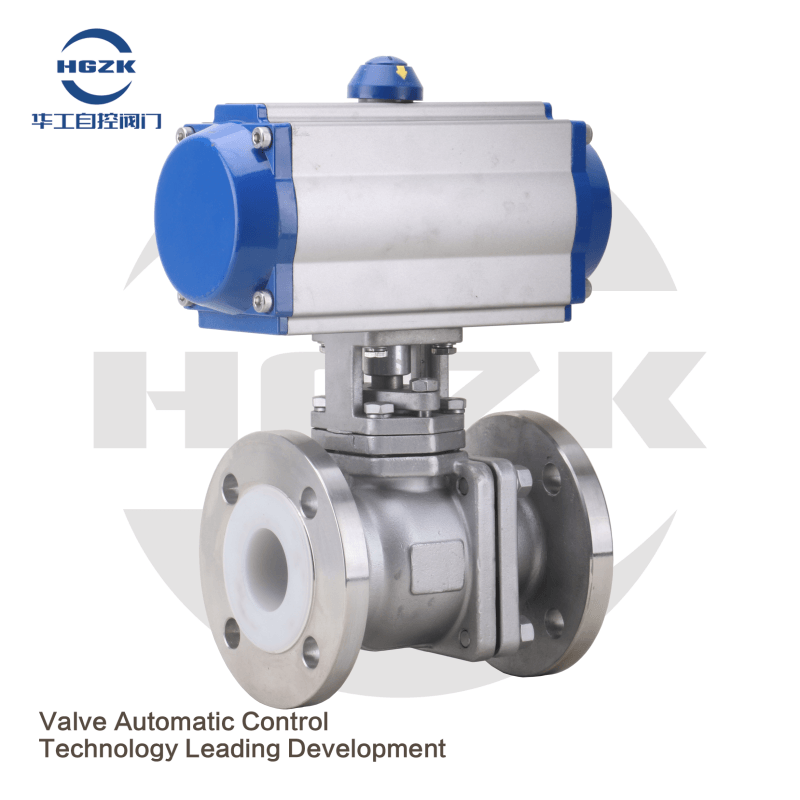

الصمام هو نوع من الأدوات الذي يلعب دورًا مهمًا في التحكم بتدفق السوائل أو الغازات داخل الأنابيب. هناك أنواع عديدة من الصمامات وكل منها له وظيفته. سنعرف المزيد عن هواكونغ الأسطوانة ذاتية التصرف والعمل المزدوج اليوم. هواكونغ: هواكونغ فاليوس هي اسم معروف في صناعة الصمامات ولها سمعة جيدة في تصنيع منتجات ذات جودة عالية.

يمكن أيضًا الإشادة بصمام الفراشة ذي الطوق المزدوج بشدة بسبب تصميمه البنيوي البسيط والأساسي. استخدام الصمام الصغير:这意味着在尺寸上较小,需要更少的空间. كما أن وزنه الخفيف يسمح لنا بتركيبه واستخدامه بسهولة. لذلك، بدلاً من أن يكون ثقيلاً وضخماً مثل أنواع أخرى من الصمامات، يمكن تركيب هذا الصمام بسهولة في المناطق الضيقة. وهذا يعني أنه يمكنك توفير تكاليف التركيب لأنه يحتل مساحة أصغر.

يأتي هذا الصمام أيضًا بمرونة. يتم استخدام الصمام الفراشة المزدوج ذو الأطراف الواسعة بشكل واسع. يمكن العثور على هذا الصمام في مختلف الصناعات مثل مصانع معالجة الكيميائيات، ومنشآت معالجة المياه، وأنظمة تدفئة وتبريد المباني. يوفر تصميمه الأسطواني التحكم الدقيق في تدفق السائل أو الغاز. حقيقة أخرى رائعة هي أنه يضمن إدارة عملية فعالة، وهو ما يصبح جانبًا مهمًا في أي تطبيق.

يتميز الصمام الفراشة المزدوج ذو الأطراف الواسعة بسهولة التركيب خاصة بالنسبة للأفراد غير المؤهلين تمامًا من صناعة الصمامات. أولاً، تأكد من أن الصمام والأنابيب التي تربطها نظيفة من الأوساخ أو الرواسب. إن العمل النظيف هو المفتاح للحصول على إغلاق جيد. بعد ذلك، ستحتاج إلى وضع أطراف الصمام في خط مستقيم مع الأنابيب. بمجرد تنسيقها، يمكنك ضبط البراغي معًا. إعادة شد البراغي أثناء تركيب الصمام أمر بالغ الأهمية للغاية. كما أنه يساعد في تقليل التسريبات لاحقًا.

أنت مسؤول تمامًا عن صيانة الصمام بعد إعداده. تعتبر الفحوصات الدورية ممارسة رائعة لضمان أن الصمام يعمل كما كان مخططًا له. تحقق من التآكل أو الأضرار أثناء هذه الفحوصات. إذا كان هناك بعض الأوساخ أو الرواسب الأخرى على أجزاء الصمام، قم بتنظيفها. ولا تنسَ تشحيم أجزاء الصمام. هذا لضمان أن يعمل الصمام بسلاسة وبدون مشاكل.

من المهم جدًا اختيار الصمام المناسب لتطبيقك المرتبط. هذا يضمن أنه سيعمل بشكل صحيح ولوقت طويل. عند اختيار صمام فراشة مزدوج الطوق، هناك نقاط مختلفة يجب مراعاتها. قبل كل شيء، فكر في السائل أو الغاز الذي سيكون داخل الصمام. هذا يختلف بناءً على نوع المادة. ثم، راقب ضغط النظام ودرجة الحرارة. يمكن لهذه العوامل أن تؤثر على طريقة عمل الصمام. وأخيرًا، اعتبر المتطلبات الخاصة لتطبيقك. هذا سيساعدك على اتخاذ القرار الصحيح.

مقارنة بأنواع أخرى من الصمامات (الصمام الكروي، صمام البوابة)، فإن صمام الفراشة المزدوج ذو الأطراف المطاطية يتمتع بعدة مزايا. أكثر ميزته وضوحًا هي كونه أكثر اقتصادية. وهذا يعني أنه أرخص في الشراء والصيانة مقارنة بأنواع أخرى من الصمامات. بالإضافة إلى ذلك، فإن هذا الصمام صغير الحجم والوزن، مما يجعله يشغل مساحة أقل. وهذا يعني أنه يمكن أن يكون خيارًا جيدًا للتطبيقات التي تعاني قيودًا في المساحة، مثل الغرف الصغيرة أو المساحات الضيقة.

دعم إرشادي. فريق خبراء ملتزم بتقديم الدعم الإرشادي. فإذا احتجتَ إلى مساعدة في اختيار المنتج المناسب — مثل صمام الفراشة ذي الفلنج المزدوج والمستخدم في التطبيقات التقنية — أو في حل المشكلات المتعلقة به، فإننا جاهزون لمساعدتك في كل خطوة. استجابة سريعة وحلٌ فعّال: نقدِّم دعمًا سريعًا وفعالًا عند ظهور أي مشكلات، ويشمل ذلك الردود الفورية على استفسارات العملاء وشواغلهم بشأن مواصفات المنتجات والدعم الفني.

صمام HGZK هو رائد في مجال حلول التحكم في السوائل. ونحن شركة مصنِّعة وتوزِّع رئيسية لمنتجات الصمامات، ومن بينها الصمامات الكهربائية والهوائية. ونوزِّع منتجاتنا في جميع أنحاء العالم لتلبية احتياجات قطاعات صناعية متنوعة. وتستخدم الشركة أنظمة حديثة للتصميم بمساعدة الحاسوب (CAD) ثلاثية الأبعاد وصمام فراشة ذا طرفين مُفلَنجَيْن لتحسين منتجاتها، التي تتميَّز بمظهرٍ جذَّابٍ وتشطيبٍ فاخرٍ. وتستعين الماكينة بعددٍ كبيرٍ من مراكز التشغيل الدقيقة لضمان دقة المكونات وتحقيق طاقة إنتاجية هائلة. وتُستخدم هذه الماكينة في تنظيم عمل جميع أنواع الصمامات، ومنها صمامات الكرة وصمامات الفراشة، كما تُستخدم أيضًا في تصنيع صمامات البوابة.

شركة ملتزمة بتقديم أفضل حلول تطابق الأنظمة ونسبة الأداء إلى السعر للصمامات البوابية ذات الفلنج المزدوج لعملائها، مع اتّخاذ التكنولوجيا المتقدمة دليلاً لها والاستفادة الكاملة من المزايا التكنولوجية. ونقوم بالتصنيع حسب الطلب والمعالجة بدءاً من التصميم وحتى الإنتاج، ومن التغليف وحتى التسليم، وفقاً لمتطلبات العملاء. كما نقدّم إدارة شاملة من نقطة واحدة، ونطلق باستمرار منتجات جديدة عالية الجودة لتلبية احتياجات عملائنا. ولدينا نطاق واسع من المحركات المصنوعة من مواد مختلفة، وهي متوفرة بعدة مواد مثل: البولي فينيل كلوريد (PVC)، والبولي بروبيلين (PP)، وفلوريد البولي فينيليدين (PVDF)، والحديد الزهر، والفولاذ المقاوم للصدأ، والفولاذ المصبوب، بالإضافة إلى النحاس. وتُدار هذه الصمامات يدوياً أو باستخدام محركات كهربائية أو هوائية أو هيدروليكية.

شركة مصنِّعة محترفة، متخصصة في صناعة صمامات التحكم الآلي، وتستند إلى سنواتٍ عديدة من الخبرة والكفاءة الفنية والتكنولوجيا المتقدمة لتقديم منتجات عالية الجودة وبأسعار تنافسية. نطاق واسع ومتنوع من المنتجات. نقدِّم مجموعة متنوعة من المحركات والصمامات لتلبية الاحتياجات المختلفة للعملاء. حلول صمامات الفراشة ذات الطرفين المُفلَنجَيْن. يمكننا تقديم خدمات التصنيع حسب الطلب (OEM/ODM) المُخصصة التي تلبي متطلباتك الفردية فيما يتعلَّق بالعلامة التجارية والهندسة. مما يسمح بالدمج السلس لمنتجاتنا في أنابيبكم. ويتمتَّع فريقنا بمهاراتٍ عالية في الدعم الفني، حيث يقدم نصائح احترافية ودعمًا فنيًّا لمساعدة العملاء على استخدام منتجاتنا بكفاءة.