×

×

Handwheel gate valves are a specific type of valve that is used for regulating the flow of liquids and gases in a piping system. To understand it, think of it like a door for the fluid that can open/close. It has round handle known as handwheel, you can rotate it with your hand easily. As you rotate the handwheel a gate moves up and down within the valve. When the gate opens, this means that liquid/gas flow through the valve may pass freely. But once that gate gits shut, it closes the floodgate for all.

It is very easy to operate the pneumatic air cylinder. The handwheel is turned to the left (counterclockwise) in order to open the valve and allow the fluid to pass through. Closing the valve to stop the flow turns the handwheel right, or clockwise. Don't overdo it while cranking the handwheel. From overdriving it, you could crush the valve. This may cause leaks or other issues that can be time-consuming and costly to repair.

Handwheel gate valves are extremely durable as they are designed to go the distance, making them an ideal option for factory areas. These valves have a great pressure tolerance hence they can work with liquids and gas being forced through the pipes. They are also capable of handling high temperatures, which is why they are frequently used in water and gas transport systems. This is the reason these valves are used so extensively in major industries such as oil and gas companies, chemical plants, and water treatment facilities. It is the reason why they are widely respected jobs as well.

There are some fabulous advantages of utilizing handwheel gate valves for the water and gas control. They provide precise control over the amount of fluid flowing through the pipes, which is one of their primary advantages. The ability to adjust the flow can prevent a ton of water and gas from being wasted, benefiting both our world and our wallets. They are also simple to install and use. This is reason why they can be seen in many factories and industrial areas. Handwheel gate valves are also crucial in stopping leaks that can be harmful and prove to be expensive due to repairs which they will require.

Proper maintenance is essential to allow handwheel gate valves to operate smoothly and serve a long life span. Regular maintenance is key! This includes inspecting the valve often, along with the stem and the handwheel keeping them clean and ensuring they are in good condition. Undercarriage rust is somewhat of an inevitability, since water, dirt, and aerial dust all contribute to the adulting pilgram fiesta hosted by your underbody. Its a real jam in there — if you see any it means time for fixing up before bigger issues arise down the line. Another effective step is to use some sort of lubricant or oil on the stem plus small moving parts. This is very useful to sustain the whole action without any stiffness or friction which could cause a problem. So as long your handwheel gate valves are being maintained very well, they can last for decades whilst being dependable.

Guidance support. Our team of experts is handwheel gate valve offering advice assistance. Whether need assistance product selection, technical specifications, troubleshooting, we're there assist at any point. Quick Response ResolutionWe prioritize prompt and effective assistance whenever issues occur, and we ensure prompt response and resolution of customer questions or concerns about specifications of the product or technical assistance.

company committed to providing our customers with system-matching options price performance ratio configuration solutions, using high-tech as the basis and fully exploiting the technological advantages. From concept production packaging our products are processed customized to meet the demands of our customers. We also provide a scientific management service is one-stop which allows us constantly to create high-quality items.We offer a variety of actuators and materials. The valves are made of PVC, PP PVDF, cast handwheel gate valve, stainless cast steel, brass and cast steel. The valves are operated by hand, pneumatic, electrical, or hydraulic actuators.

Professional Manufacturer. are experts in AUTO Control Valves and we make use our vast expertise, experience the latest technologies to offer top-quality products at reasonable prices. A wide range product. offer a wide range handwheel gate valve actuators, accommodating requirements a variety of industries and uses to meet the diverse needs of our clients. Customized Solutions. offer flexible OEM/ODM options to meet unique needs in terms of branding and engineering. This guarantees seamless integration of our products into pipelines. Our team is awash with technical experience, providing expert support and consultancy services to ensure that customers are able to understand and make use of our products properly.

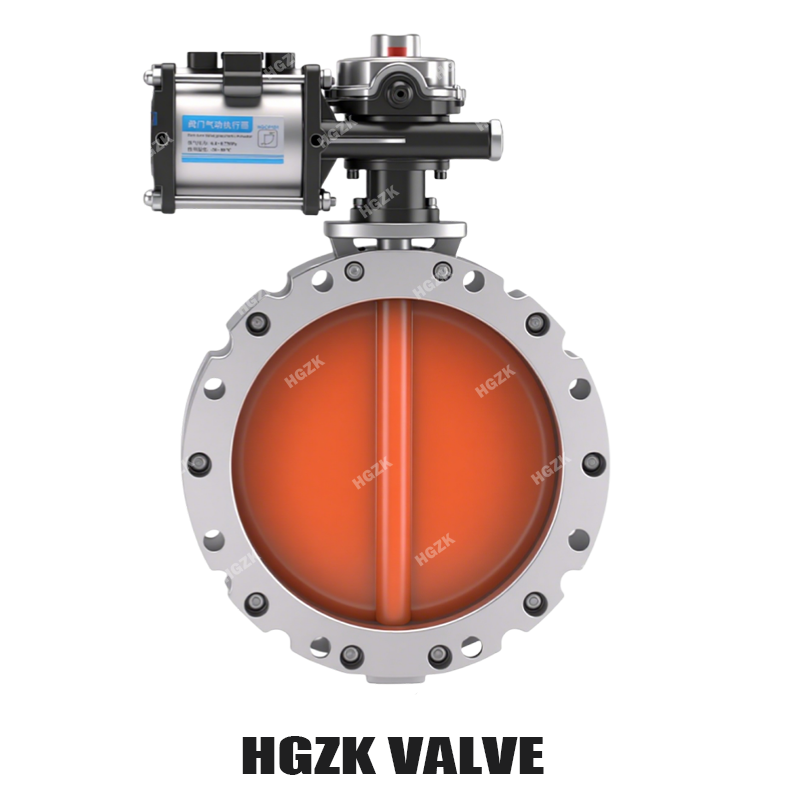

We welcome you HGZK VALVE, a leading manufacturer Fluid Control solution. We a renowned producer distributor valves such as pneumatic and electric valves. offer our products globally to meet demands various industries. products of the company are designed by using a cutting-edge CAD 3D design system, which only has a stunning appearance, but also a reliable quality. The equipment uses a number of precision machining centers to handwheel gate valve precision the parts and provide huge production capacities. Widely used in various types of regulating valves, ball valves, butterfly valves gate valves, slurry valves globe valves, plug valves and many more valves.